Injection Molding Services

Full Service Custom Injection Molding Since 1976

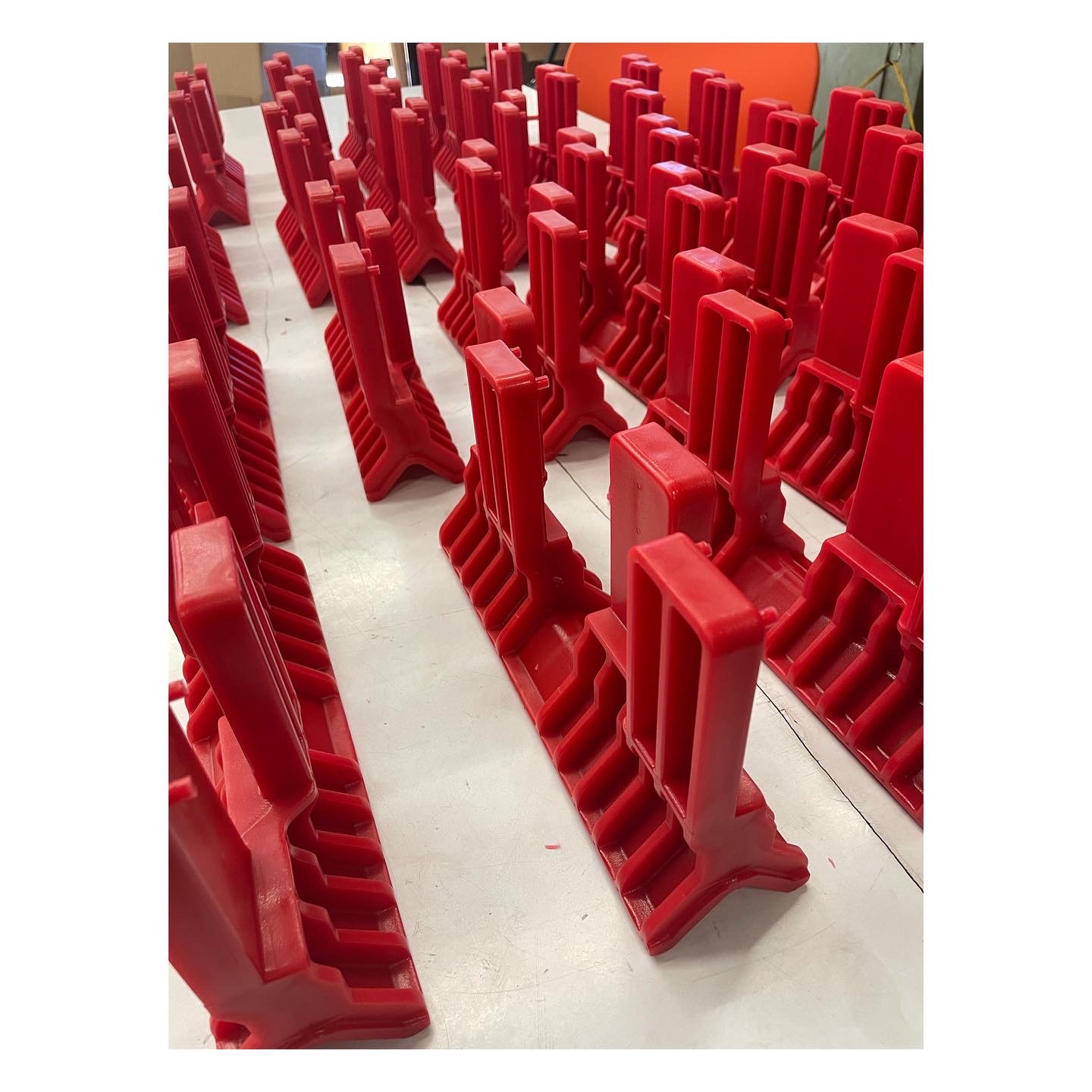

- High Quality Injection Molded Parts Custom Made in the USA

- Experts in a Wide Variety of Industries, Materials, Sizes, and Applications

- Large Array of Injection Molding Presses for Most Part Sizes

- 50+ Years Experience in Insert Molding & Overmolding

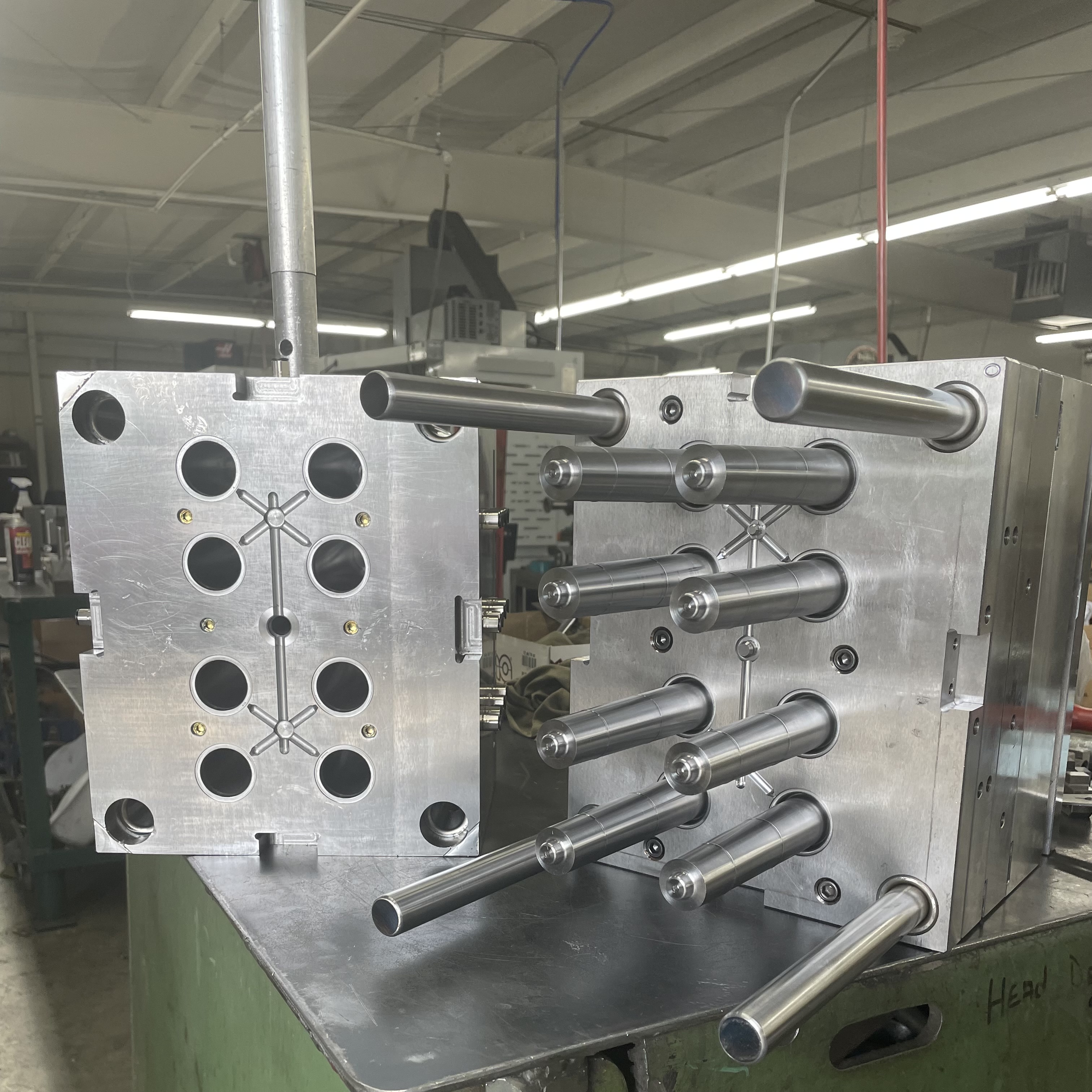

Texlon Plastics provides precise, high quality injection molded products for all applications. Our in-house tooling and design engineering team handle every project with highly detailed expertise, saving customers time and money. All parts are quality inspected to ensure customer satisfaction and quick turnaround times keep our customer's supply chain flowing.

Our plastic parts are produced with engineering grade resins to ensure strong and long-lasting products. We offer a wide range of thermoplastic materials allowing our customers to ensure quality products.

We can reverse engineer parts from samples or drawings, or from a supplied CAD file. Here are some of the industries we currently serve:

- Textiles

- Material Handling

- Automotive

- Electronic Housings

- Forklift Parts

- Custom Inventions

- Medical Devices

- Firearm Accessories

- Furniture Parts

- Game Calls

- Insert Molding

- Parts for Manufacturing Processes

- Plastic Fasteners

- Food Processing

- Pump Parts

- Textile Machine Parts

-

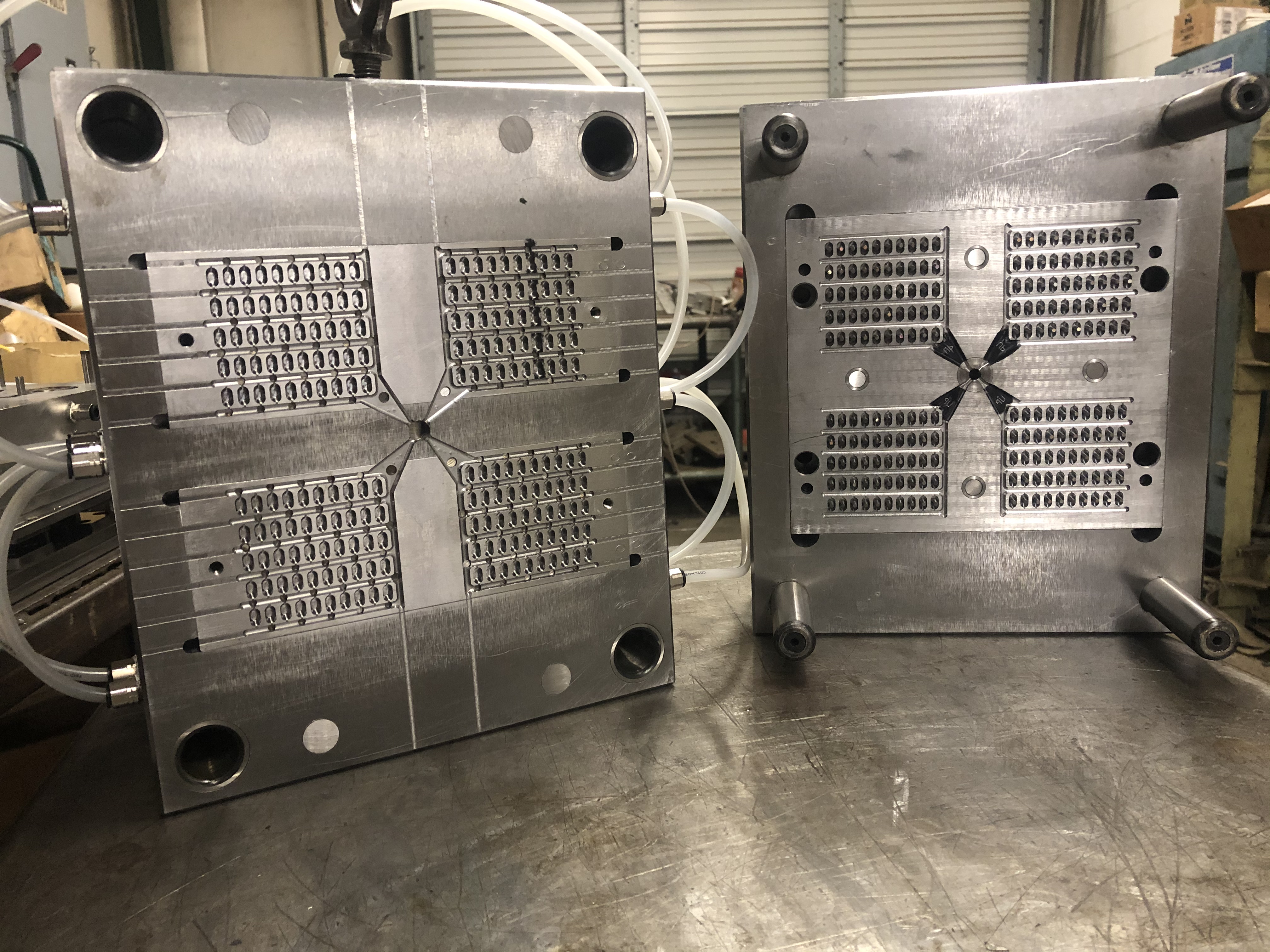

200 Cavity Injection Mold for Face Mask Adjusting from Design to Manufacturing

200 Cavity Mold for facemask adjustment part from design to manufacturing in 7 days. After a 2nd identical mold was engineered, over 55 million pieces were produced over a 7 week period during supply chain shortages and the pandemic. Custom made in North Carolina, USA...

-

Covid Face Shields for Healthcare Workers

This project went from a 3D design to full production in just 2.5 days to supply local healthcare workers in the Carolinas with proper PPE during massive supply chain shortages. ...

ABS stands for Acrylonitrile Butadiene Styrene, which is a common thermoplastic polymer used in injection molding processes. It's known for its versatile properties, making it suitable for a wide range of applications, including automotive parts, electronic housings, consumer goods, toys, and more.

Here's what the individual components of ABS refer to:

· Acrylonitrile: This component provides chemical resistance and hardness to the ABS material. It helps make ABS more durable and capable of withstanding various environmental conditions.

· Butadiene: Butadiene contributes to the toughness and impact resistance of ABS. This component allows the material to absorb energy without fracturing, making it suitable for products that may experience sudden impacts or stress.

· Styrene: Styrene provides the shiny and smooth surface finish to ABS products. It also contributes to the material's rigidity and processability during injection molding.

In injection molding processes, ABS pellets or granules are melted and injected into a mold under high pressure. The molten ABS material takes the shape of the mold cavity, and once it cools and solidifies, the mold is opened to reveal the finished product. ABS is favored for injection molding due to its excellent flow properties, dimensional stability, and ease of processing.

Key advantages of ABS in injection molding include:

· Good Impact Resistance: ABS can absorb impact energy, making it suitable for parts that may experience rough handling or sudden impacts.

· Surface Finish: ABS parts often have a smooth and glossy finish, requiring minimal post-processing to achieve an appealing appearance.

· Chemical Resistance: ABS has decent resistance to chemicals, which makes it suitable for applications that might be exposed to various substances.

· Dimensional Stability: ABS exhibits relatively low shrinkage during cooling, resulting in parts with better dimensional accuracy and stability.

· Wide Range of Colors: ABS can be easily colored with pigments, allowing for a variety of color options without compromising material properties.

· Ease of Processing: ABS has good melt flow characteristics, making it well-suited for injection molding and allowing for complex shapes to be easily produced.

However, there are some considerations with ABS as well. It can be prone to warping or cracking if not properly controlled during the cooling process. Also, exposure to UV light can cause it to degrade over time, leading to color fading and reduced mechanical properties. Some ABS formulations might also have issues with odor emissions during processing.

Overall, ABS is a popular choice for injection molding due to its balance of strength, toughness, and processability, making it suitable for a wide range of consumer and industrial products.

Nylon is a popular thermoplastic material that is commonly used in injection molding processes. Injection molding is a manufacturing technique in which molten plastic material is injected into a mold cavity, where it cools and solidifies to form the desired shape. Nylon's unique properties make it well-suited for injection molding applications.

Here's how nylon is typically used in injection molding processes:

- Material Selection: Nylon comes in various grades, each with its own set of properties, such as strength, flexibility, heat resistance, and more. Engineers select the appropriate nylon grade based on the requirements of the final product.

- Material Preparation: Nylon pellets are usually used as the raw material for injection molding. Before the molding process, the nylon pellets are preheated to a specific temperature to ensure proper melting and flow during injection.

- Injection: The preheated nylon pellets are fed into the injection molding machine's hopper. The pellets are then melted in the machine's barrel and forced into the mold cavity through a nozzle. The mold is designed to create the desired shape of the final product.

- Cooling and Solidification: Once the molten nylon is injected into the mold, it rapidly cools upon contact with the cold walls of the mold. This cooling process solidifies the nylon and allows it to take on the shape of the mold cavity.

- Ejection: After the nylon has solidified and the part has sufficiently cooled, the mold opens, and the newly formed nylon part is ejected from the mold cavity. Ejector pins or other mechanisms may be used to facilitate the removal of the part from the mold.

- Post-Processing: Depending on the specific application, the nylon part may undergo additional post-processing steps, such as trimming excess material, adding surface finishes, or assembling with other components.

Nylon's key characteristics that make it suitable for injection molding include:

- Strength and Durability: Nylon is known for its excellent mechanical properties, including high tensile and impact strength, making it suitable for producing sturdy parts.

- Heat Resistance: Many nylon grades have good heat resistance, allowing them to withstand elevated temperatures without deforming or losing their mechanical properties.

- Chemical Resistance: Nylon is resistant to many chemicals, oils, and solvents, making it suitable for applications where exposure to such substances is likely.

- Low Friction: Nylon has a low coefficient of friction, which can be advantageous for applications where parts need to slide or move against each other smoothly.

- Dimensional Stability: Nylon has relatively low moisture absorption, leading to better dimensional stability in humid conditions compared to some other plastics.

Nylon's versatility and wide range of properties have led to its use in various industries, including automotive, consumer goods, electronics, and industrial equipment. However, it's important to note that working with nylon requires understanding its specific characteristics and the nuances of the injection molding process to achieve optimal results.

HIPS stands for High Impact Polystyrene, which is a type of thermoplastic material used in various manufacturing processes, including injection molding. HIPS is a combination of polystyrene and rubber, which gives it enhanced impact resistance compared to standard polystyrene.

Here's how HIPS is used in injection molding processes:

- Material Selection: HIPS is chosen based on its properties, particularly its high impact resistance, dimensional stability, and ease of processing. It is often used when a balance of affordability and impact resistance is required.

- Material Preparation: HIPS is supplied in the form of pellets or granules. These pellets are typically pre-dried to remove any moisture content, as moisture can affect the quality of the final molded parts. Preheating might also be necessary to ensure consistent melting and flow during injection.

- Injection: The preheated HIPS pellets are fed into the hopper of an injection molding machine. Inside the machine, the pellets are heated and melted within a barrel. The molten HIPS is then injected into a mold cavity under high pressure using a nozzle.

- Cooling and Solidification: Once injected into the mold, the molten HIPS material quickly cools and solidifies upon contact with the cold surfaces of the mold. The cooling process takes only a short amount of time, as the thin walls of the mold allow for rapid heat transfer.

- Ejection: After the HIPS has solidified and cooled sufficiently, the mold opens, and the newly formed part is ejected from the mold cavity. Ejector pins or other mechanisms aid in the removal of the part from the mold.

- Post-Processing: Depending on the specific requirements of the application, the HIPS part might undergo additional processes such as trimming, assembly, surface finishing, or painting.

HIPS is commonly used in injection molding for several reasons:

- Impact Resistance: HIPS's primary advantage is its high impact resistance, making it suitable for applications that require durable and rugged parts. It can withstand moderate levels of mechanical stress and impact without breaking.

- Cost-Effectiveness: HIPS is relatively affordable compared to some other engineering plastics, making it an economical choice for manufacturing.

- Ease of Processing: HIPS is easy to process during injection molding, allowing for faster cycle times and efficient production.

- Surface Finish: HIPS typically has a smooth surface finish, making it suitable for applications where appearance matters.

HIPS is used in a wide range of products, including consumer goods, packaging, toys, electronics, automotive components (interior trim parts), and more. Its combination of affordability, impact resistance, and ease of processing makes it a popular choice for manufacturers seeking a balance between performance and cost.

Polyethylene (PE) is a widely used thermoplastic polymer that belongs to the polyolefin family. It is derived from ethylene monomers and comes in various forms, each with different properties. Polyethylene is known for its versatility, durability, and chemical resistance. It is commonly used in a variety of applications, including packaging, containers, pipes, toys, and more.

Injection molding is one of the processes in which polyethylene is frequently used. Here's how polyethylene is used in injection molding:

- Material Selection: Different grades of polyethylene are chosen based on the specific requirements of the end product. The two most common types of polyethylene used in injection molding are Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE). LDPE offers flexibility and impact resistance, while HDPE provides stiffness, strength, and excellent chemical resistance.

- Material Preparation: Polyethylene is typically supplied in the form of pellets or granules. These pellets might require drying before processing to remove any moisture, which could affect the quality of the final part. Preheating might also be necessary to ensure uniform melting and flow during injection.

- Injection: The preheated polyethylene pellets are introduced into the hopper of an injection molding machine. Inside the machine, the pellets are heated and melted within a barrel. The molten polyethylene is then injected into a mold cavity through a nozzle under high pressure.

- Cooling and Solidification: Once inside the mold, the molten polyethylene rapidly cools and solidifies against the cold surfaces of the mold. The cooling process is relatively quick due to the high thermal conductivity of polyethylene and the thin walls of the mold.

- Ejection: After the polyethylene has sufficiently cooled and solidified, the mold opens, and the molded part is ejected from the mold cavity. Ejector pins or other mechanisms facilitate the removal of the part from the mold.

- Post-Processing: Depending on the intended application, the polyethylene part might undergo additional processing steps such as trimming, assembly, surface finishing, or printing.

Polyethylene is chosen for injection molding for various reasons:

- Chemical Resistance: Polyethylene exhibits excellent chemical resistance, making it suitable for applications where the part will come into contact with various chemicals or solvents.

- Versatility: Different grades of polyethylene can be used to achieve a wide range of properties, from flexible and impact-resistant to rigid and durable.

- Low Water Absorption: Polyethylene has low water absorption, contributing to its dimensional stability and suitability for outdoor applications.

- Cost-Effective: Polyethylene is often cost-effective compared to other engineering plastics, which makes it a preferred choice for large-scale production.

Polyethylene's diverse properties and applications have solidified its place as one of the most commonly used plastics in the world. It can be found in everyday products across numerous industries due to its durability, versatility, and ease of processing using methods like injection molding.

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic material that is commonly used for its optical clarity, high impact resistance, and weatherability. It's often used as a glass substitute due to its excellent light transmission properties and resistance to shattering.

In injection molding, acrylic is used to create a wide range of products that require transparency, smooth surfaces, and precise shapes. Here's how acrylic is used in injection molding processes:

- Material Selection: Acrylic is chosen for its optical properties, including transparency and light transmission. It's often selected when a clear and aesthetically pleasing appearance is essential. Acrylic grades may vary based on factors like UV resistance, impact resistance, and flame-retardant properties.

- Material Preparation: Acrylic is supplied in the form of pellets or granules. It doesn't usually require preheating before injection molding. However, drying the material before processing can help prevent defects caused by moisture.

- Injection: The acrylic pellets are loaded into the hopper of an injection molding machine. Inside the machine, the pellets are melted within a barrel and then injected into a mold cavity through a nozzle. Acrylic requires careful control of injection parameters to prevent defects like bubbles or flow marks.

- Cooling and Solidification: After injection, the molten acrylic quickly cools and solidifies as it comes into contact with the cold mold surfaces. Achieving proper cooling is essential to prevent warping or internal stresses in the molded part.

- Ejection: Once the acrylic has cooled and solidified adequately, the mold opens, and the molded acrylic part is ejected from the mold cavity. Ejector pins or other mechanisms help facilitate the removal of the part from the mold.

- Post-Processing: Depending on the application, acrylic parts might undergo additional processes such as trimming, polishing, or coating to achieve the desired final appearance and quality.

Acrylic is particularly well-suited for injection molding due to its properties:

- Optical Clarity: Acrylic offers excellent transparency, making it suitable for applications where a clear view or light transmission is necessary, such as windows, lenses, and displays.

- Impact Resistance: Acrylic has good impact resistance, making it less prone to shattering compared to glass. This property is valuable for products that require both clarity and safety.

- Weatherability: Acrylic is resistant to UV radiation and weathering, which makes it suitable for outdoor applications where prolonged exposure to sunlight is expected.

- Surface Finish: Acrylic parts can be molded with smooth and glossy surfaces, minimizing the need for post-molding finishing processes.

Acrylic is used in various industries, including automotive, electronics, medical devices, signage, lighting fixtures, and consumer goods. Its ability to combine optical clarity with mechanical properties makes it a popular choice for injection molding applications that demand both aesthetic appeal and functionality.

ASA stands for Acrylonitrile Styrene Acrylate, which is a type of thermoplastic material that combines the properties of three different monomers: acrylonitrile, styrene, and acrylate. ASA is known for its excellent weather resistance, UV stability, and durability, making it particularly suitable for outdoor applications. It's often used as a substitute for ABS (Acrylonitrile Butadiene Styrene) due to its improved weatherability.

In injection molding, ASA is utilized to create parts that require both mechanical strength and resistance to outdoor environmental conditions. Here's how ASA is used in injection molding processes:

- Material Selection: ASA is chosen for its combination of properties, including UV resistance, impact strength, and dimensional stability. It's often chosen for applications where parts will be exposed to sunlight, temperature fluctuations, and outdoor elements.

- Material Preparation: ASA is supplied as pellets or granules. Before injection molding, it's important to ensure that the material is dry, as moisture can negatively impact the quality of the final molded parts.

- Injection: The preheated ASA pellets are introduced into the injection molding machine's hopper. Inside the machine, the pellets are heated and melted within a barrel. The molten ASA is then injected into a mold cavity through a nozzle under high pressure.

- Cooling and Solidification: Once inside the mold, the molten ASA rapidly cools and solidifies against the cold surfaces of the mold. Cooling is crucial to achieve proper dimensional accuracy and prevent warping or distortion.

- Ejection: After the ASA has cooled and solidified sufficiently, the mold opens, and the molded part is ejected from the mold cavity. Ejector pins or other mechanisms help facilitate the removal of the part from the mold.

- Post-Processing: Depending on the specific requirements of the application, the ASA part might undergo additional processes such as trimming, surface finishing, painting, or assembly.

ASA's key properties make it suitable for injection molding:

- Weather Resistance: ASA exhibits excellent weather resistance and UV stability, making it a reliable choice for outdoor applications where exposure to sunlight, temperature changes, and environmental elements is expected.

- Impact Strength: ASA offers good impact resistance, ensuring that molded parts can withstand mechanical stress and sudden impacts.

- Dimensional Stability: ASA's low coefficient of thermal expansion contributes to its dimensional stability, making it less prone to warping under temperature fluctuations.

- Surface Finish: ASA parts can be molded with smooth surfaces and vibrant colors, reducing the need for extensive post-processing or painting.

ASA is commonly used in industries such as automotive (exterior components), construction (roofing, siding), outdoor equipment (lawn and garden products), and signage. Its ability to withstand outdoor conditions while maintaining mechanical properties makes it a preferred choice for applications that require both durability and aesthetics.

Styrolux is a transparent copolymer that combines the properties of polystyrene and polybutadiene. It is known for its clarity, impact resistance, and processability. Styrolux is often used in applications where transparency, aesthetics, and toughness are important. It is commonly utilized as a clear alternative to general-purpose polystyrene and can be processed using methods like injection molding.

Here's how Styrolux is used in injection molding processes:

- Material Selection: Styrolux is chosen for its optical properties, impact resistance, and ease of processing. It is often selected when a clear appearance and good impact performance are essential.

- Material Preparation: Styrolux is supplied in pellet or granule form. Prior to injection molding, it's important to ensure that the material is dry, as moisture can negatively affect the quality of the final molded parts.

- Injection: Preheated Styrolux pellets are introduced into the injection molding machine's hopper. Inside the machine, the pellets are heated and melted within a barrel. The molten Styrolux is then injected into a mold cavity through a nozzle under high pressure.

- Cooling and Solidification: Once inside the mold, the molten Styrolux quickly cools and solidifies against the cold surfaces of the mold. Proper cooling is crucial to achieve accurate dimensions and prevent distortion.

- Ejection: After the Styrolux has cooled and solidified sufficiently, the mold opens, and the molded part is ejected from the mold cavity. Ejector pins or other mechanisms assist in the removal of the part from the mold.

- Post-Processing: Depending on the application's requirements, the Styrolux part might undergo additional processes such as trimming, polishing, or assembly.

Styrolux's key properties make it suitable for injection molding:

- Clarity: Styrolux offers excellent optical clarity, making it suitable for applications where transparency is important.

- Impact Resistance: Styrolux provides good impact resistance, allowing molded parts to endure mechanical stress and impacts.

- Processability: Styrolux is designed for easy processing, making it suitable for injection molding and other manufacturing methods.

- Surface Finish: Styrolux parts can be molded with smooth surfaces, reducing the need for extensive post-molding finishing.

Styrolux is commonly used in various industries, including packaging, consumer goods, household products, and automotive components (like clear lenses or covers). Its combination of clarity and toughness makes it a popular choice when both aesthetics and performance are essential for the end product.

Polycarbonate (PC) is a versatile and highly durable thermoplastic material known for its exceptional impact resistance, optical clarity, and high heat resistance. It is commonly used in applications that require transparency, strength, and resistance to a wide range of environmental conditions. Injection molding is a prominent method for processing polycarbonate due to its complex shapes and intricate designs.

Here's how polycarbonate is used in injection molding processes:

- Material Selection: Polycarbonate is chosen for its combination of properties, including impact resistance, transparency, heat resistance, and dimensional stability. It is often used when a clear appearance and robust mechanical performance are essential.

- Material Preparation: Polycarbonate is typically supplied in pellet or granule form. While preheating is generally not required for polycarbonate, ensuring that the material is free from moisture is important to maintain part quality.

- Injection: Preheated polycarbonate pellets are introduced into the injection molding machine's hopper. Inside the machine, the pellets are heated and melted within a barrel. The molten polycarbonate is then injected into a mold cavity through a nozzle under high pressure.

- Cooling and Solidification: Once inside the mold, the molten polycarbonate quickly cools and solidifies against the cold surfaces of the mold. Proper cooling is critical to achieving precise dimensions and preventing warping or distortion.

- Ejection: After the polycarbonate has cooled and solidified sufficiently, the mold opens, and the molded part is ejected from the mold cavity. Ejector pins or other mechanisms facilitate the removal of the part from the mold.

- Post-Processing: Depending on the application's requirements, the polycarbonate part might undergo additional processes such as trimming, assembly, or surface finishing.

Polycarbonate's key properties make it suitable for injection molding:

- Impact Resistance: Polycarbonate is known for its outstanding impact resistance, making it suitable for applications where parts need to withstand mechanical stress and potential impacts.

- Optical Clarity: Polycarbonate offers excellent optical clarity, making it valuable for applications where transparency is crucial, such as lenses, windows, and display screens.

- Heat Resistance: Polycarbonate exhibits high heat resistance, allowing it to retain its properties at elevated temperatures without significant degradation.

- Dimensional Stability: Polycarbonate's low coefficient of thermal expansion contributes to its dimensional stability, even in changing temperature conditions.

- Toughness: Polycarbonate's toughness, combined with its other properties, makes it a reliable choice for parts that need to maintain their integrity over time.

Polycarbonate is widely used in various industries, including automotive (headlamp lenses, interior components), electronics (device housings, display panels), medical devices (transparent covers), and consumer goods. Its balance of strength, transparency, and heat resistance makes it a favored material for injection molding applications where performance, aesthetics, and durability are vital.

PETG, short for Polyethylene Terephthalate Glycol-Modified, is a thermoplastic copolyester that combines the properties of PET (Polyethylene Terephthalate) with glycol modification for enhanced clarity, toughness, and impact resistance. PETG is commonly used in various applications due to its transparency, ease of processing, and suitability for both injection molding and extrusion processes.

Here's how PETG is used in injection molding processes:

- Material Selection: PETG is chosen for its clarity, toughness, and ease of processing. It is often selected when a clear appearance and good impact performance are important.

- Material Preparation: PETG is supplied in pellet or granule form. It typically doesn't require preheating before injection molding. However, it's important to ensure that the material is free from moisture to maintain part quality.

- Injection: Preheated PETG pellets are introduced into the injection molding machine's hopper. Inside the machine, the pellets are heated and melted within a barrel. The molten PETG is then injected into a mold cavity through a nozzle under high pressure.

- Cooling and Solidification: Once inside the mold, the molten PETG rapidly cools and solidifies against the cold mold surfaces. Proper cooling is essential to achieve accurate dimensions and prevent warping or distortion.

- Ejection: After the PETG has cooled and solidified sufficiently, the mold opens, and the molded part is ejected from the mold cavity. Ejector pins or other mechanisms aid in the removal of the part from the mold.

- Post-Processing: Depending on the application's requirements, the PETG part might undergo additional processes such as trimming, surface finishing, or assembly.

PETG's key properties make it suitable for injection molding:

- Clarity: PETG offers good optical clarity, making it suitable for applications where transparency is important, such as packaging, displays, and consumer goods.

- Impact Resistance: PETG provides good impact resistance, allowing molded parts to withstand mechanical stress and impacts.

- Ease of Processing: PETG is easy to process during injection molding, which contributes to faster cycle times and efficient production.

- Chemical Resistance: PETG is resistant to many chemicals and solvents, which is valuable in applications where the part may come into contact with various substances.

- Food Contact Approval: Some PETG formulations are approved for food contact applications due to their non-toxic nature and resistance to chemical migration.

PETG is used in various industries, including packaging, medical devices, consumer goods, and displays. Its combination of transparency, toughness, and ease of processing makes it a versatile material for injection molding applications where both aesthetics and performance are important.

Acetal, also known as polyoxymethylene (POM), is a high-performance engineering thermoplastic known for its excellent mechanical properties, dimensional stability, and resistance to wear and chemicals. It is commonly used in applications that require tight tolerances, durability, and low friction. Acetal is often used in injection molding due to its processability and ability to produce intricate shapes with precision.

Here's how acetal is used in injection molding processes:

- Material Selection: Acetal is chosen for its combination of properties, including high strength, low friction, and chemical resistance. It is often selected when parts need to maintain tight tolerances and exhibit excellent mechanical performance.

- Material Preparation: Acetal is supplied in pellet or granule form. While it typically doesn't require preheating before injection molding, ensuring that the material is dry is important to maintain part quality.

- Injection: Preheated acetal pellets are introduced into the injection molding machine's hopper. Inside the machine, the pellets are heated and melted within a barrel. The molten acetal is then injected into a mold cavity through a nozzle under high pressure.

- Cooling and Solidification: After injection, the molten acetal cools and solidifies rapidly against the cold mold surfaces. Proper cooling is crucial to achieve accurate dimensions and prevent warping or distortion.

- Ejection: Once the acetal has cooled and solidified sufficiently, the mold opens, and the molded part is ejected from the mold cavity. Ejector pins or other mechanisms facilitate the removal of the part from the mold.

- Post-Processing: Depending on the application's requirements, the acetal part might undergo additional processes such as trimming, surface finishing, or assembly.

Acetal's key properties make it suitable for injection molding:

- Mechanical Strength: Acetal exhibits high tensile strength and stiffness, making it suitable for applications that require load-bearing and structural components.

- Low Friction: Acetal's low coefficient of friction makes it ideal for parts that need to slide or move against other surfaces with minimal wear.

- Chemical Resistance: Acetal is resistant to a wide range of chemicals, which is valuable in applications where the part may come into contact with various substances.

- Dimensional Stability: Acetal has low moisture absorption and excellent dimensional stability, maintaining its shape and performance over time.

Acetal is used in various industries, including automotive (gears, bearings), consumer goods (zippers, handles), electronics (connectors, switches), and industrial machinery (pumps, valves). Its combination of mechanical strength, low friction, and chemical resistance makes it a preferred choice for injection molding applications where precision, durability, and performance are essential.

Polypropylene (PP) is a widely used thermoplastic polymer known for its versatility, chemical resistance, and relatively low cost. It is commonly used in applications that require lightweight and durable parts with good mechanical properties. Polypropylene can be easily processed through injection molding to create a wide range of products.

Here's how polypropylene is used in injection molding processes:

- Material Selection: Polypropylene is chosen for its combination of properties, including lightweight, chemical resistance, and good impact strength. It is often selected when parts need to be durable, resistant to chemicals, and cost-effective.

- Material Preparation: Polypropylene is supplied in pellet or granule form. It typically doesn't require preheating before injection molding. Ensuring that the material is dry is important to maintain part quality.

- Injection: Preheated polypropylene pellets are introduced into the injection molding machine's hopper. Inside the machine, the pellets are heated and melted within a barrel. The molten polypropylene is then injected into a mold cavity through a nozzle under high pressure.

- Cooling and Solidification: After injection, the molten polypropylene cools and solidifies rapidly against the cold mold surfaces. Proper cooling is essential to achieve accurate dimensions and prevent warping or distortion.

- Ejection: Once the polypropylene has cooled and solidified sufficiently, the mold opens, and the molded part is ejected from the mold cavity. Ejector pins or other mechanisms facilitate the removal of the part from the mold.

- Post-Processing: Depending on the application's requirements, the polypropylene part might undergo additional processes such as trimming, surface finishing, or assembly.

Polypropylene's key properties make it suitable for injection molding:

- Lightweight: Polypropylene is lightweight, making it suitable for applications where weight reduction is important.

- Chemical Resistance: Polypropylene is resistant to a wide range of chemicals, making it valuable for applications where the part may come into contact with various substances.

- Good Impact Strength: Polypropylene offers good impact resistance, allowing molded parts to withstand mechanical stress and impacts.

- Cost-Effectiveness: Polypropylene is relatively cost-effective compared to some other engineering plastics, making it a preferred choice for larger-scale production.

Polypropylene is used in various industries, including automotive (interior components, bumpers), packaging (containers, caps), consumer goods (toys, furniture), and industrial products (piping, containers). Its balance of properties and cost-effectiveness makes it a versatile choice for injection molding applications where durability, chemical resistance, and affordability are important.

Advantages of Injection Molding

Texlon Plastics stands out as a premier provider of injection molding services, offering a host of advantages crucial for diverse industries. Specializing in the efficient production of large quantities, Texlon Plastics ensures high-speed manufacturing with a focus on precision and complexity. The company's commitment to consistency and repeatability is evident in the production of intricately shaped components, facilitated by the versatility of materials available in injection molding. Texlon Plastics' services prove cost-effective for large-scale productions, minimizing waste through material recycling. With seamless automation integration, the company enhances production efficiency and maintains a commitment to design flexibility, enabling the creation of innovative and unique products. Texlon Plastics excels in delivering parts with superior surface finishes and fine details, making them a trusted partner for businesses of all sizes and stages—from prototyping to high-volume production—reflecting the scalability and reliability inherent in their injection molding services.

Materials Available

Texlon Plastics, a distinguished provider of injection molding services, offers a diverse range of materials tailored to meet specific client needs. Specializing in the injection molding process, Texlon employs an array of thermoplastics, including Polyethylene, Polypropylene, Polystyrene, Polyvinyl Chloride, and Polycarbonate, among others. Additionally, the company utilizes thermosetting plastics such as Phenolic and elastomers like Silicone and Polyurethane. Texlon Plastics is well-versed in engineering plastics like Nylon, Polyethylene terephthalate, and Acetal, ensuring suitability for varied applications. With a commitment to innovation, the company may also explore biodegradable options such as Polylactic Acid. This comprehensive material selection allows Texlon Plastics to deliver high-quality, precisely molded components, meeting the diverse and stringent requirements of its clientele.

Industries Served

As a leading provider of injection molding services, Texlon Plastics serves an array of industries by delivering high-quality plastic components with precision and efficiency. In the automotive sector, Texlon contributes to the production of interior and exterior components, while in the consumer goods industry, the company manufactures packaging, containers, and toys. The electronics industry benefits from Texlon's expertise in crafting casings and connectors for electronic devices. Additionally, Texlon plays a vital role in the medical field by producing components for medical devices, ensuring precision and cleanliness. The aerospace industry relies on Texlon for lightweight, high-strength components, while the packaging industry benefits from the company's efficiency in producing containers and closures. Texlon Plastics also contributes to the construction sector with parts like pipe fittings, and the company's reach extends to appliances, toys, industrial equipment, sporting goods, and furniture. With a diverse portfolio and a commitment to meeting industry-specific requirements, Texlon Plastics is a trusted partner across various sectors, offering expertise in material selection, mold design, and the cost-effective production of plastic components.