Portfolio

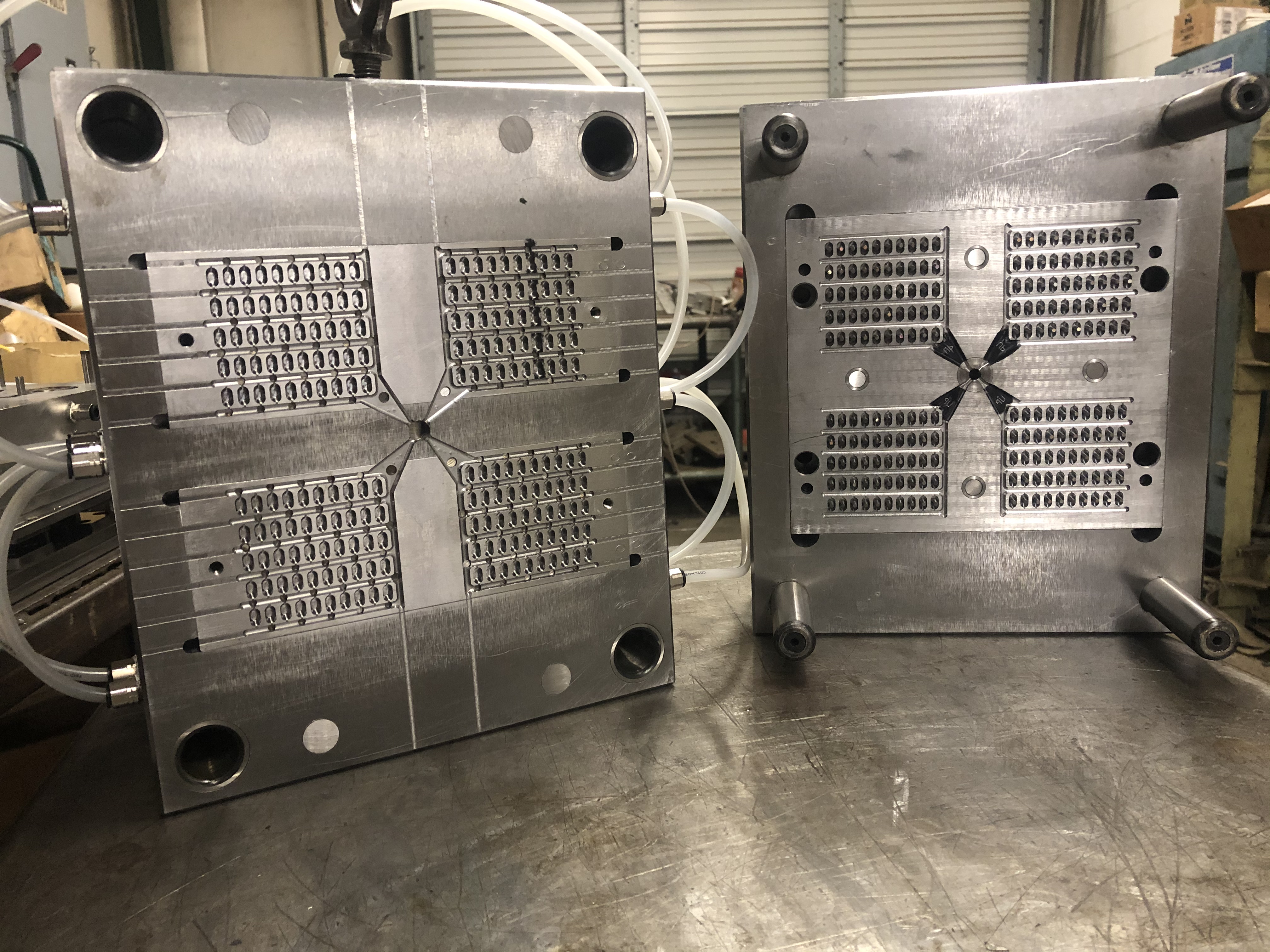

200 Cavity Injection Mold for Face Mask Adjusting from Design to Manufacturing

200 Cavity Mold for facemask adjustment part from design to manufacturing in 7 days. After a 2nd identical mold was engineered, over 55 million pieces were produced over a 7 week period during supply chain shortages and the pandemic. Custom made in North Carolina, USA...

Covid Face Shields for Healthcare Workers

This project went from a 3D design to full production in just 2.5 days to supply local healthcare workers in the Carolinas with proper PPE during massive supply chain shortages. ...

HVAC Drain Device

Texlon Plastics was contracted to design, prototype, and mass produce this injection molded product. 3 different molds were constructed and all parts are molded out of ABS. ...

Injection Molded Spool

One of our newest projects coming to life. Texlon Plastics was responsible for part design, mold design, making the custom injection mold, and manufacturing the final product. All work done in North Carolina, USA....

Custom Propylene Plastic Parts - Reading Tool for Children

Texlon Plastics recently collaborated with OTTER Reading to manufacture custom propylene plastic parts designed for OTTER Reading’s Phonics Builders, an innovative, multi-sensory educational tool. Using advanced injection molding technology, Texlon Plastics produced durable, lightweight, and child-friendly components that help students engage in phonics and spelling exercises aligned with the IMSE curriculum. The Phonics Builders allow students to manipulate sounds, decode words with soft...

Two-Halves Housing Mold for Wireless Networking Equipment

This project involved the production of a two-piece electronic housing used in the networking industry, specifically for devices that enable over-the-air (OTA) updates on wireless networks. The enclosure is created using a family mold, which is a tooling configuration that allows two different yet complementary parts to be injection molded simultaneously. These two components are the mating halves of the final product housing. The material of choice for this application is a Polycarbo...

Chrysler Windshield Wiper Motor Restoration

This project focused on the professional rebuilding of Chrysler windshield wiper motors with a commitment to authenticity, performance, and durability. Each unit begins with a numbers-correct original windshield wiper motor, which is carefully disassembled, inspected, and restored to OEM specifications. To improve long-term reliability and address a known weakness in the original design, special attention has been given to the internal three-speed gear mechanism. The original large plastic driv...

Injection Molded Components for Road Construction Signage

This project involved the design and production of two custom injection-molded nylon components used in road construction, specifically for “STOP/SLOW” signs. These parts work together to allow the sign’s pole to telescope upward, increasing its height for enhanced visibility and improved safety on roadways. Both components are manufactured using 4-cavity molds, producing four identical parts per cycle to maximize efficiency and output. The smaller cap is particularly complex ...